Focus on the design and manufacture

of membrane switch and membrane panelProfessional development and design, trustworthy

Products in every industry have many names misunderstood, or there is no special name, at most there is a name accepted by most people. But over time, the variety of products increases, and different ways of saying them become more varied. The following explains the difference between membrane panel, switch, button and drum type panel, personal opinion.

First of all, look up a relatively official explanation of these words, and here I will directly baidu, quoting the Encyclopedia.

Thin film switch is an operating system which integrates key function, indicating element and instrument panel. It consists of four parts: panel, upper circuit, isolation layer and lower circuit. Press the membrane switch, the contact of the upper circuit deforms downward, and the contact of the plate of the lower circuit is conductive. After the finger is released, the contact of the upper circuit bounces back, the circuit is disconnected, and the loop triggers a signal.

Thin film button, is a PET thin sheet with contact (including metal shrapnel is also called pot piece), used in PCB, FPC and other circuit boards as a switch, between the user and the instrument plays an important role of tactile switch.

Film panel is in PVC, PC, PET and other flexible plastic materials printed on the established graphics, text instructions and other materials with different double-sided adhesive produced for identification and protection of plastic products.

There are various names: 1) membrane switch 2) membrane touch keyboard 3) sticker 4) mask 5) conductive circuit 6) button switch 7) face paste 8) touch switch, etc.

First of all, in terms of use, this is a panel. Due to the production process, PET, PVC, PC, and even acrylic are generally used to print patterns through the screen printing technology. If the panel has modeling needs, or window needs, also need to die cutting, in order to match the panel modeling.

On the basis of the panel, if the customer's product itself has designed buttons on the PCB board, it needs the cooperation of the film panel, at this time, the film panel needs to increase the bulge. The design of drum pack needs to cooperate with the height of the product keys, so that the panel is not stiff when it is pressed. This type of panel can be called bulge type membrane panel.

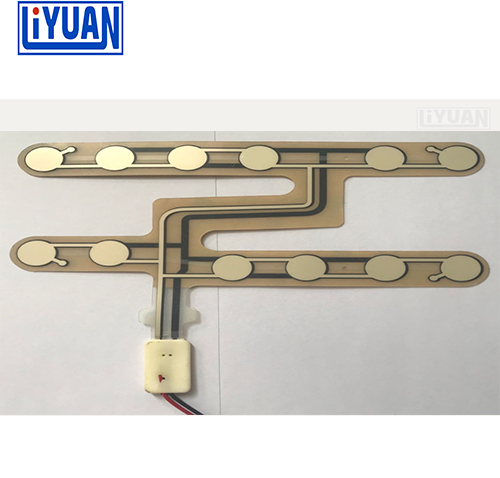

At the next level, if the customer's product provides only one interface, there is no switching function. Bulge type membrane panel needs to increase flexible lines, there are different types of keys as switch contact, currently more use pot piece. Pot pieces are oval, triangle, cross, round, depending on the shape of the product needs, match the panel drum set. The material and surface processing of pot slices depend on the user's hand feeling and the number of times of button life.

The above is the difference between membrane panel, bulging membrane panel and membrane switch.

service

service