Focus on the design and manufacture

of membrane switch and membrane panelProfessional development and design, trustworthy

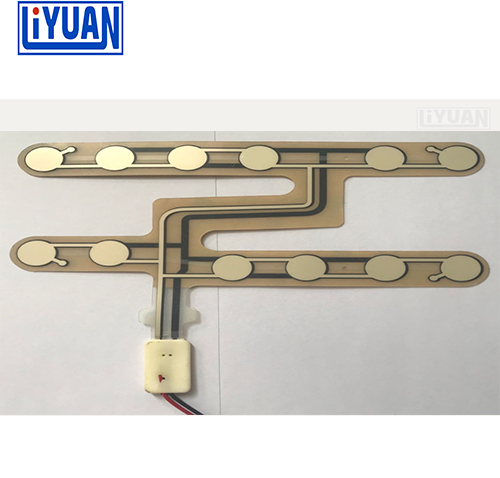

There are many kinds of membrane switches, including flat, convex, flexible, hard and so on. The manufacture of thin film switch has certain requirements on the panel. Panels also protect the appearance of goods. Therefore, when making thin film panel, the thin film must meet certain conditions to make a good thin film switch.

First, the appearance is good, the appearance should be smooth and shiny. No mechanical operation, scratches, inclusions, color spots and other appearance defects. Secondly, weather resistance is better, in certain natural environmental conditions, do not be out of shape, cracking, aging, discoloration. Chemical resistance is good, face plate layer can have urgent different chemical, but to most common chemical, be like alcohol kind, ether kind, mineral oil kind, should have certain tolerance.

In general, buttons on membrane switches use color only to express the direction, shape, and size of the key body. In this way, the accuracy of the operation can only be identified by the operator's vision, because there is no appropriate reflection information to indicate whether the finger is pressed on the useful scale of the switch to make the switch action, thus affecting the arrogance and operation speed of the whole machine monitoring. A thin film switch, which makes the key body of the switch slightly raised, slightly higher than the panel, forming a three-dimensional shape, called a three-dimensional key switch.

service

service